Lithium-ion batteries, including LiFePO4 batteries, have a tendency to develop an imbalance between the cells during charging and discharging. This is because the cells in a battery pack may not be perfectly matched in terms of their capacity, resistance, and other characteristics. As a result, some cells may end up taking on more or less of a load than others, which can cause them to overcharge or overdischarge.

A battery management system (BMS) is designed to address this issue by monitoring the state of each cell in the battery pack and ensuring that they are charged and discharged within a safe range. The BMS does this by controlling the flow of current to and from the cells, and by shutting down the charging or discharging process if any of the cells reach an unsafe voltage level.

In the case of LiFePO4 batteries, a BMS is particularly important because these batteries are more sensitive to overcharging and overdischarging than other types of lithium-ion batteries. Without a BMS, the cells in a LiFePO4 battery pack could be damaged or even fail completely, which would reduce the overall performance and lifespan of the battery.

Types of balancers (BMS)

There are several different types of battery management systems (BMS) that can be used to balance the cells in a lithium-ion battery pack. Here are a few examples:

Passive BMS

A passive BMS is a simple system that monitors the state of the cells in a battery pack, but does not actively control the flow of current to and from the cells. Instead, it relies on the charging and discharging circuitry to limit the current and prevent the cells from reaching an unsafe voltage level. Passive BMS systems are relatively inexpensive and easy to implement, but they offer less protection than other types of BMS systems.

Active BMS

An active BMS is a more sophisticated system that can actively control the flow of current to and from the cells in a battery pack. This is typically done using a series of switching devices, such as MOSFETs or relays, which can be turned on and off to regulate the flow of current. Active BMS systems are more expensive and complex than passive systems, but they offer more precise control over the charging and discharging process, and can provide better protection for the cells in the battery pack.

Inductive BMS

An inductive BMS uses inductive couplers (also known as transformers) to transfer energy and information between the BMS and the cells in a battery pack. The BMS can use this information to monitor the state of the cells and control the flow of current to and from the cells as needed. Inductive BMS systems are generally more reliable than systems that rely on physical connections, but they are also more expensive and may not be as accurate as other types of BMS systems.

Capacitive BMS

A capacitive BMS uses a network of capacitors to transfer energy and information between the BMS and the cells in a battery pack. Like inductive BMS systems, capacitive systems are generally more reliable than systems that rely on physical connections, but they may not be as accurate as other types of BMS systems.

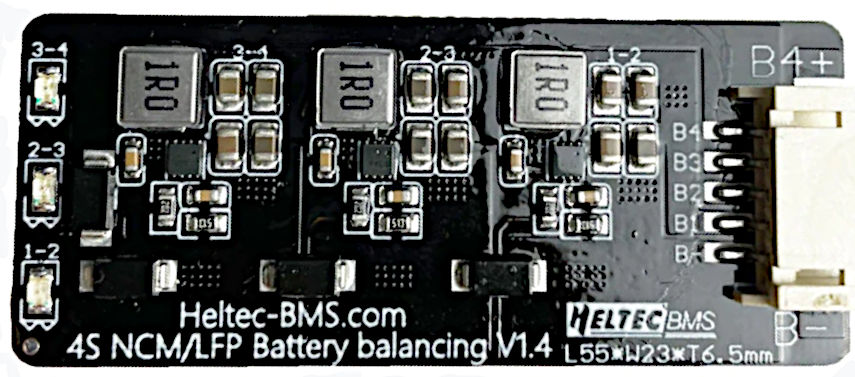

HELTEC BMS 1.2A LiFePO4 balancer

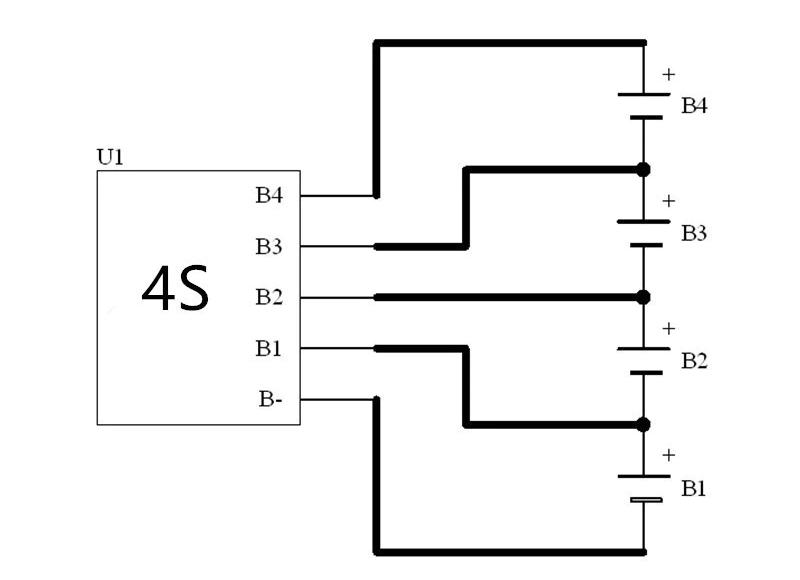

The HELTEC 1.2A LiFePO4 balancer is a small power board I got off AliExpress. It's an inductive BMS that can balance a 4-cell LiFePO4 battery with up to 1.2 A of balancing current between adjacent cells.

According to the manufacturer's specs, the balancing process starts at a voltage difference of 0.1 V between adjacent cells. The balancing current is proportional to the cell voltage difference and can reach a maximum of 1.2 A when the cell voltage difference is greater than or equal to 0.2 V.

The balancing continues as long as the cell voltage difference is above 0.03 V, stops when the value goes below that threshold, and is independent of the working status of the battery, meaning that it continues while charging, discharging, or when the battery is at rest.

The declared quiescent current is 0.01 mA, which is an acceptable value that can make a medium sized battery last for a few months when unused. There is also a convenient balancing monitoring feature with 3 LEDs that indicate when the board is balancing cells 1-2, 2-3, and 3-4. When all the LEDs are off, the battery is balanced.

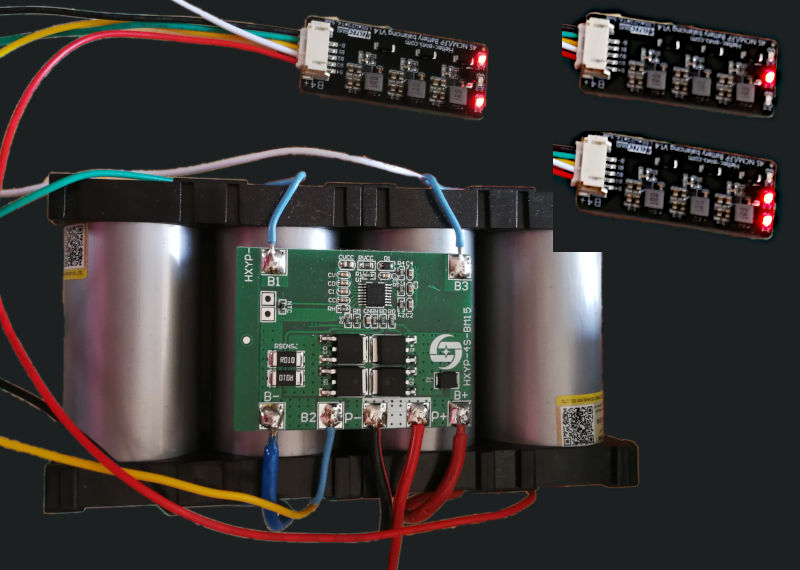

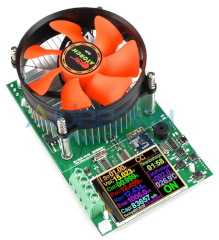

I tested the HELTEC 1.2A LiFePO4 balancer with a 4-cell 6500 mA/h LiFePO4 battery of the Chinese brand LiitoKala and a

digital battery discharger which provided a constant discharge current of 2 A.

I got all of this equipment from AliExpress (links provided at the end of the article).

In the picture below, you can see my system in different balancing modes.

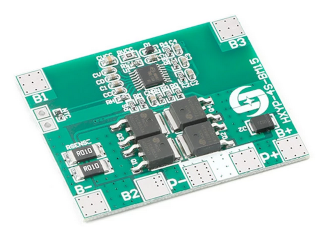

The HELTEC 1.2A Lifepo4 balancer does not provide any kind of battery protection such as overcharge, overdischarge or short circuit, that's why I added an additional board visible in the pictures above, on top of the battery pack.

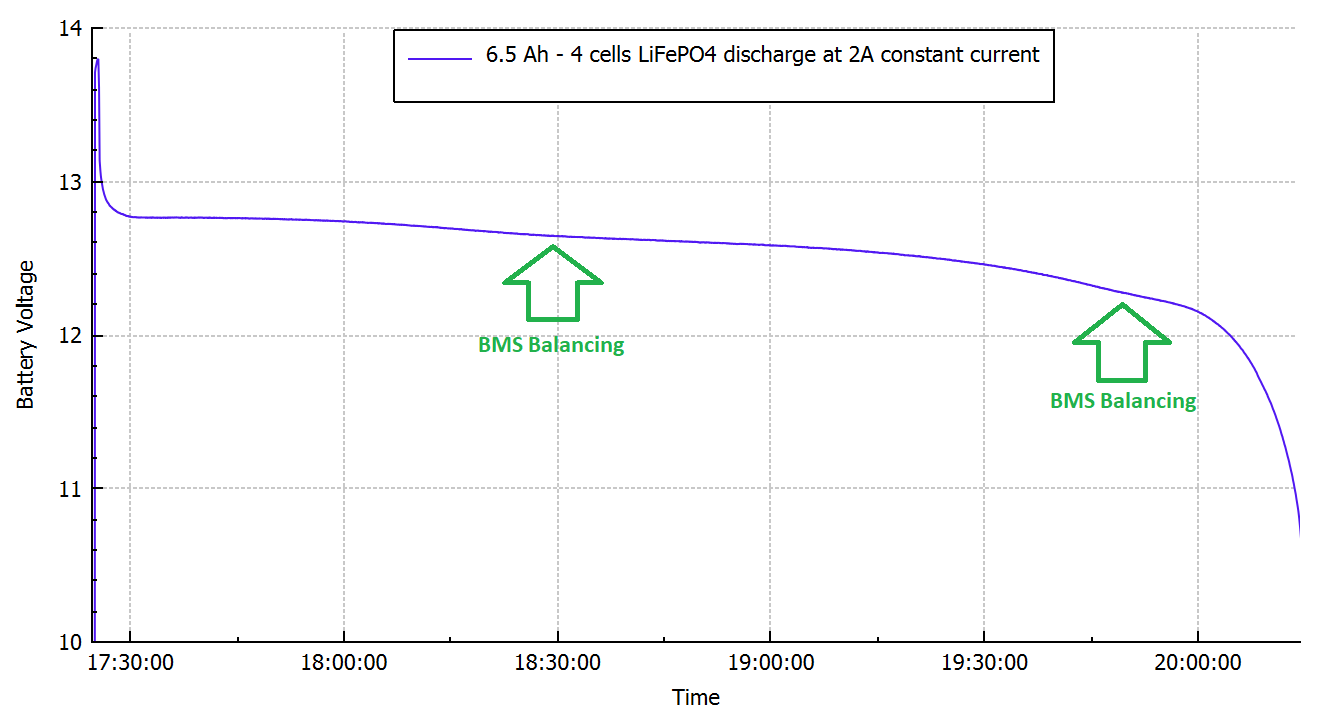

I recorded the voltage values during the whole discharge cycle and built the chart below, in which the balancing action is clearly visible.

Here is a list of all the equipment used in this review:

|

|

| HELTEC 1.2A Lifepo4 balancer | |

|

|

| Digital battery tester - dummy load | |

|

|

| LiFePO4 4S battery protection board | |

|

|

| Liitokala 6500mAh LiFePO4 batteries |